These piping systems are used in industries like oil and gas, power generation, and chemical processing, where pipes carry fluids or gases at extreme temperatures. Without proper support, these pipes can experience stress, wear, or even failure, leading to costly downtime or dangerous accidents. This article will explore the key factors to consider when selecting pipe clamps for high-temperature environments and provide solutions for ensuring secure, long-lasting support.

1. Why Pipe Clamps Are Important in High-Temperature Systems

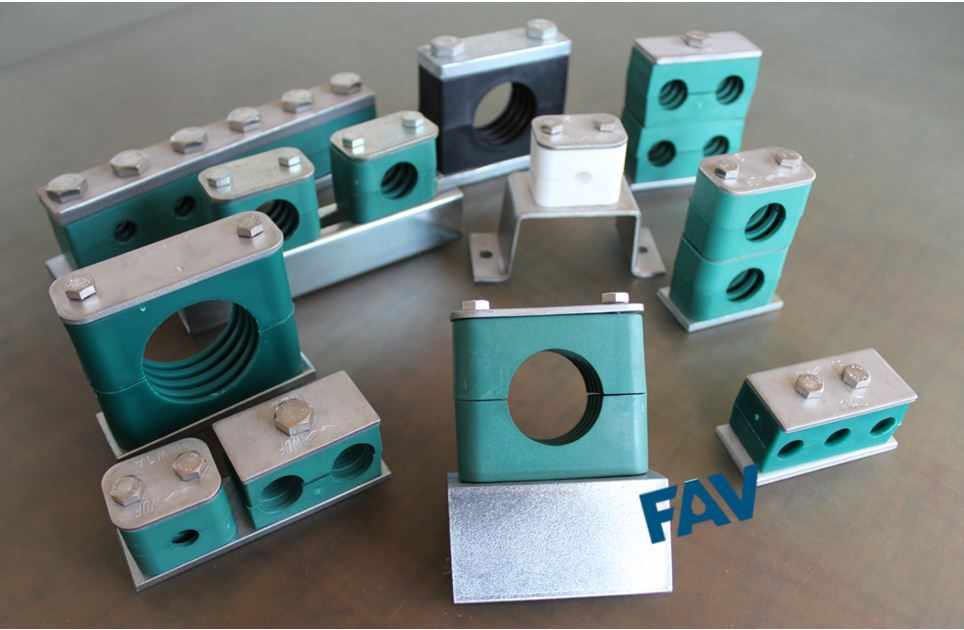

Pipe clamps play a vital role in supporting and securing pipes in place, especially in systems where pipes are exposed to high temperatures. High-temperature environments put additional stress on piping systems, causing expansion, contraction, and vibration. Without the right pipe clamps, these forces can lead to misalignment, leakage, or pipe damage. Pipe clamps are designed to keep the pipes stable, reduce movement, and prevent the pipes from wearing out prematurely.

2. Key Challenges of High-Temperature Piping Systems

High temperatures can cause pipes to expand and contract, which puts stress on the entire system. In addition, extreme heat can degrade materials over time, weakening the pipes and the clamps holding them. Vibration from equipment, pressure fluctuations, and thermal cycling (repeated heating and cooling) also add to the challenges. In these conditions, ordinary pipe clamps might fail, making it necessary to choose high-quality clamps specifically designed for high-temperature use.

3. Materials Used in High-Temperature Pipe Clamps

The choice of materials for pipe clamps is critical in high-temperature environments. Common materials used for high-temperature pipe clamps include:

Stainless Steel: This material is highly resistant to heat, corrosion, and rust, making it one of the best choices for high-temperature piping systems. Stainless steel maintains its strength and durability, even at elevated temperatures, ensuring that the pipe clamp can withstand thermal stress over time.

Carbon Steel: Carbon steel is another popular material for pipe clamps in high-temperature settings. It offers good strength and heat resistance but may require additional coatings to prevent corrosion in certain environments.

Alloy Steels: In some extreme applications, alloy steels, such as Inconel or Hastelloy, are used due to their excellent resistance to high temperatures, oxidation, and corrosion.

Choosing the right material for your pipe clamp ensures it will last longer and perform well in extreme conditions.

4. Thermal Expansion and Pipe Clamp Design

Thermal expansion occurs when pipes expand as they heat up. This can cause pipes to shift, leading to stress on both the pipes and the clamps holding them. To account for this, the design of the pipe clamp must allow for movement while still providing support. Sliding pipe clamps or clamps with expansion guides can help accommodate this movement. These designs allow the pipe to expand and contract without becoming misaligned or putting excessive pressure on the clamp itself.

5. Vibration Dampening in High-Temperature Clamps

In high-temperature systems, vibrations are a common issue, especially in industries like power generation or oil refining, where heavy machinery operates near piping. Excessive vibrations can weaken pipe clamps and cause damage to both the pipes and surrounding structures. Vibration-dampening pipe clamps are designed to absorb these vibrations, reducing wear on the pipes and ensuring that the clamps remain securely in place. These clamps often come with special inserts made of heat-resistant materials that help absorb the energy from vibrations.

6. Corrosion Resistance for Long-Term Durability

High-temperature environments often go hand in hand with corrosive conditions, especially in industries that handle chemicals or steam. Over time, corrosion can weaken both the pipes and the pipe clamps, leading to leaks or even structural failures. Corrosion-resistant coatings or materials like stainless steel are essential for pipe clamps in these environments. Some clamps also come with protective linings or coatings that prevent corrosion, ensuring that they maintain their integrity even in harsh conditions.

7. Clamping Pressure and Pipe Integrity

The amount of pressure applied by the pipe clamp is crucial, especially in high-temperature systems. If the clamp is too tight, it can damage the pipe as it expands and contracts. On the other hand, if the clamp is too loose, it won’t provide adequate support. Adjustable pipe clamps allow for fine-tuning the clamping pressure, ensuring the right balance between holding the pipe securely and allowing for natural expansion and contraction. Using adjustable clamps can prevent unnecessary wear on the pipe and prolong the life of both the piping system and the clamp.

8. Fireproof Pipe Clamps for Extreme Heat

In some high-temperature environments, such as refineries or chemical plants, pipes may be exposed to fire risks. In these cases, fireproof pipe clamps are necessary. These clamps are designed to withstand direct exposure to flames without losing their structural integrity. Fireproof clamps are often made from special alloys or come with heat-resistant coatings that can endure extreme heat for extended periods. They help ensure that the piping system remains intact during emergency situations, providing an extra layer of safety.

9. Easy Maintenance and Inspection of High-Temperature Pipe Clamps

Regular maintenance and inspection are critical to ensuring the long-term reliability of pipe clamps in high-temperature systems. Over time, heat can cause clamps to degrade or lose their effectiveness. Choosing pipe clamps that are easy to access and inspect can simplify the maintenance process. Removable or split pipe clamps allow for quick inspections and repairs without the need to dismantle the entire system. Regular checks for signs of wear, corrosion, or loosening help prevent unexpected failures.

10. Choosing the Right Pipe Clamp for Your System

When selecting a pipe clamp for high-temperature applications, it's important to consider the specific conditions of your system, such as the maximum operating temperature, the materials being transported, and any additional environmental factors like vibration or corrosion. Consulting with pipe clamp manufacturers and understanding the technical specifications of different clamps can help you choose the best option for your needs. Investing in high-quality, durable pipe clamps designed for high-temperature environments can improve the safety and efficiency of your entire piping system.

Conclusion

By understanding these key elements and prioritizing high-quality, corrosion-resistant, and durable pipe clamps, businesses can ensure long-term success and avoid costly downtime or equipment failures. Investing in the right pipe clamp solution today can lead to safer, more efficient operations in the future.

Write a comment ...